The estimated annual losses caused by counterfeit components in the electronics industry reach up to $250 billion, posing a serious threat to original equipment manufacturers (OEMs). Where do these components come from, and why are they so dangerous? Find answers to these questions, along with recommendations on mitigating the risks of counterfeit components below.

What are counterfeit electronic components?

A counterfeit electronic component is an unauthorized or illegal replica of a genuine product or its parts, produced by parties other than the original manufacturer. These components can take various forms, such as unauthorized copies, substitutes, and fraudulently altered, remarked, or re-topped components.

As a rule, counterfeit components often exhibit lower quality than legitimate ones. Not only may they fail to meet the standards of components provided by the original manufacturer but can also deviate from intended specifications. Yet, many can maintain desirable performance under ideal conditions, making their detection challenging. However, fluctuations in conditions can lead to the failure of these elements.

Despite the inferior quality and performance of counterfeit electronic components compared to original products, malicious players offer these substitutes at prices similar to legitimate elements, deceiving unsuspecting customers.

Find more at: https://asselems.com/en/preventing-the-supply-chain-from-counterfeit-components

How can counterfeit electronic components affect OEMs?

Counterfeit electronic elements can cause a wide range of serious and costly issues, some of which are described below:

Compromised quality

Even a single counterfeit element in an electronic device can result in the product’s non-compliance with its performance specifications. This poses potential safety hazards and decreases device reliability, increasing the likelihood of defects, malfunction, and premature failure. Additionally, the use of a counterfeit element may make repairs more challenging and costly.

Loss of customers' trust

Infiltration of counterfeit components, especially if they impact customer safety, can severely damage the brand's position in the market. The loss of trust in a product can be detrimental to the original equipment manufacturer's brand.

Regulatory compliance risks

Non-compliance with industry standards and regulations not only poses a safety hazard for customers but also subjects OEMs to legal consequences. Offering goods that involve counterfeit elements can result in regulatory compliance issues.

Supply chain disruption

If faulty products reach customers, devices may be rejected at the last stage of the supply chain. Identifying the root problem requires investigating quality issues and searching for vendors supplying legitimate components, which further disrupts the regular operation of the supply chain.

Financial damage

Nearly all the issues mentioned above are associated with considerable expenses. Supply chain and production disruption, customer rejections, and loss of brand reputation are factors caused by counterfeit elements that contribute to significant financial losses.

Mitigating risks of counterfeit components

Fortunately, it is possible to minimize the risk of counterfeit components. For instance, Poland-based contract electronics manufacturer Assel works only with vendors who are found trustworthy and reliable after thorough screening. Additionally, this EMS provider has implemented a robust traceability system and regular testing of components provided by vendors.

While the chances of encountering counterfeit components are especially high during market shortages, an experienced EMS provider is aware of potential threats and takes proactive measures to mitigate these risks.

Production resistant to counterfeit elements

Working with an experienced EMS provider, who offers professional supply management, has a network of reliable electronic component suppliers, and thoroughly tests all components used for manufacturing, can help you avoid issues caused by counterfeit components. To learn more about working with such a contract manufacturer, visit https://asselems.com/

Mahesh Babu, Priyanka Chopra Jonas and Prithviraj Sukumaran joins SSMB29 Getty Images

Mahesh Babu, Priyanka Chopra Jonas and Prithviraj Sukumaran joins SSMB29 Getty Images  Mahesh Babu’s dramatic new look for SSMB 29 sparks a social media frenzy as fans compare him to Mufasa and a Hollywood action hero Getty Images/ Twitter

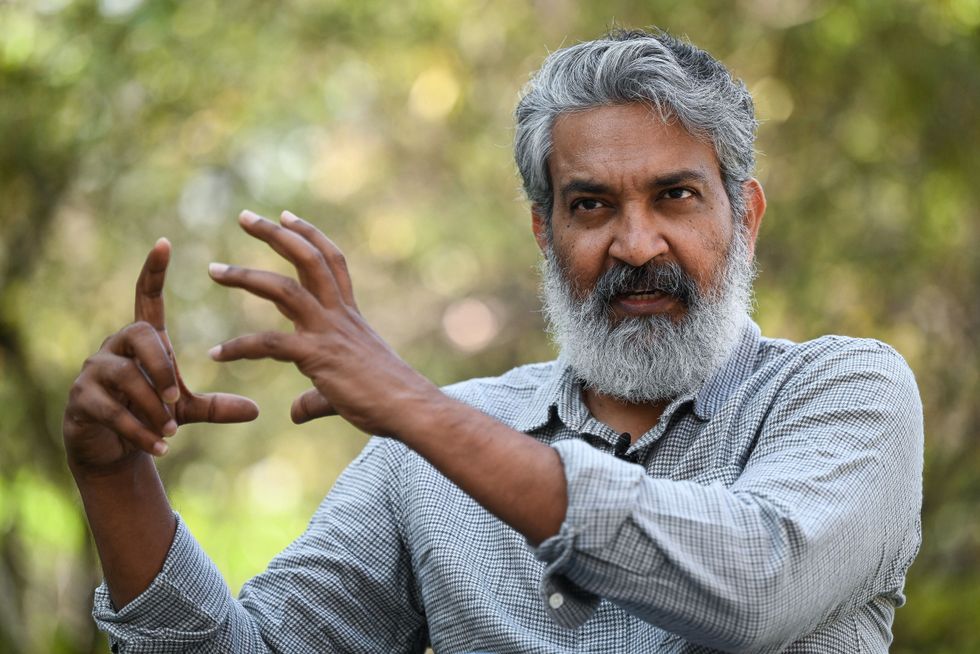

Mahesh Babu’s dramatic new look for SSMB 29 sparks a social media frenzy as fans compare him to Mufasa and a Hollywood action hero Getty Images/ Twitter  SS Rajamouli recreates Varanasi at Ramoji Film City for a key action sequence in SSMB29 Getty Images

SS Rajamouli recreates Varanasi at Ramoji Film City for a key action sequence in SSMB29 Getty Images  Priyanka Chopra calls 'SSMB29' her homecoming as she reunites with Indian cinema Getty Images

Priyanka Chopra calls 'SSMB29' her homecoming as she reunites with Indian cinema Getty Images

Angel Swift enters Love Island with power to dump rival as dramatic twist stuns villaInstagram/

Angel Swift enters Love Island with power to dump rival as dramatic twist stuns villaInstagram/